Menu

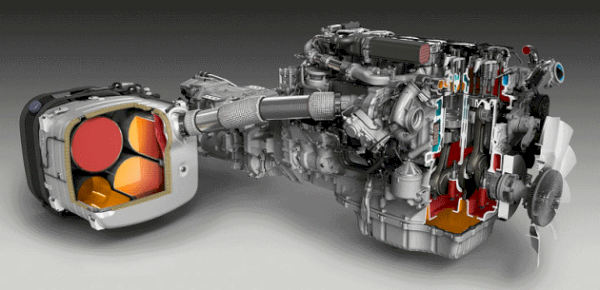

Close collaboration between Scania AB and Idé-Pro Skive has resulted in a revolutionary new oil sump. The development of this prototype was a major challenge.

‘Scania contacted us for our help in manufacturing the first prototypes of a new thermoplastic oil sump,’ says Morten Frandsen, Idé-Pro. ‘The particular challenge was to produce an injection moulding tool that ensured that the large plastic blank did not become warped.’

‘Our skilled tool designers used advanced MoldFlow simulations so that we actually produced a crooked mould that resulted in perfectly straight bottom vessels.’

The assignment is one of many examples of how our extensive knowledge of prototypes and advanced analyses can be used to advise on a development project. Once the prototype is approved, we transfer our knowledge and experience from prototype production to the final manufacturer - in this case Plastal Group AB, which produces plastic car parts and the plastic supplier Dupont.

Dupont writes in its press release

"Having settled on the initial design and material, Scania contacted Idé-Pro to undertake the first steps in the parts' development. Idé-Pro not only produces tools and moulds parts, but also offers the development tools and expertise needed during the prototype stage.. In such a way the design of the mould could be optimized to minimize warpage."

At Idé-Pro, we mould and cast prototypes in the same material and process as in serial production, so they can be used directly in the final construction, for testing, etc. The design specifications are the same as with traditional die casting.

Please contact us directly by email or phone if you need to have technical items moulded.