Menu

Injection moulding is an advanced manufacturing process, used in our plastic production to create precise and complex plastic parts.

As experienced plastic manufacturers, we offer injection moulding of prototypes and serial production in various types of thermoplastics. Here we mould in materials such as polystyrene, polypropylene and polyethylene, but also offer injection moulding in more sustainable alternatives such as bioplastics and recycled plastics.

Our expertise, experienced team of technicians and state-of-the-art production facilities ensure we maintain high quality standards and deliver results that meet your injection moulding requirements.

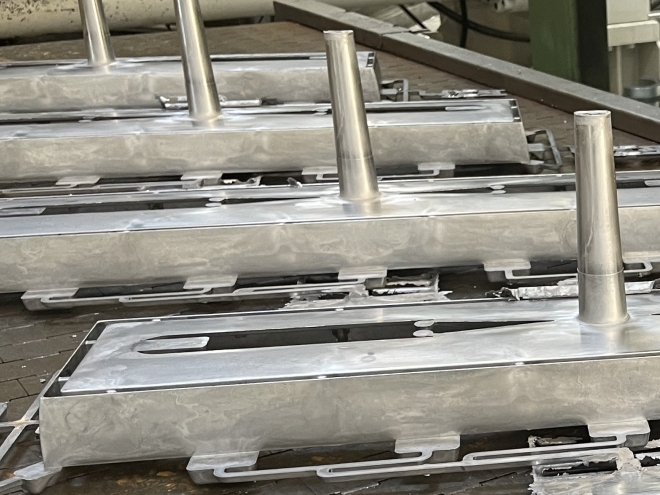

High pressure die casting (HPDC) is a process for manufacturing metal parts by forcing molten metal into a mould under high pressure.

Our focus is on prototyping and small series production in the materials aluminium, magnesium and zinc, and we use a wide range of alloys to meet our customers' requirements. With a dedication to precision and quality, we also offer extensive machining options, including 5-axis and 3-axis CNC milling.

In addition to CNC machining, we also offer a range of other treatments after HPDC, such as various surface treatments.

Our expertise in moulding also includes expanded polystyrene (EPS), expanded polypropylene (EPP) and other foamed materials for serial production as well as prototypes for serial production.

EPS/EPP moulding involves heating the material and then using steam to expand the beads and form a shape. It is a versatile method that combines lightweight, insulation and mouldability. The process allows for a wide range of applications and is an effective solution for producing customised parts in a variety of industries.

No matter which moulding or casting method you need, our focus is always on precision and quality. We strive to deliver parts that fulfil your requirements and expectations.

Contact us today to discuss how we can use our expertise in prototyping and serial production to realise your projects.