Menu

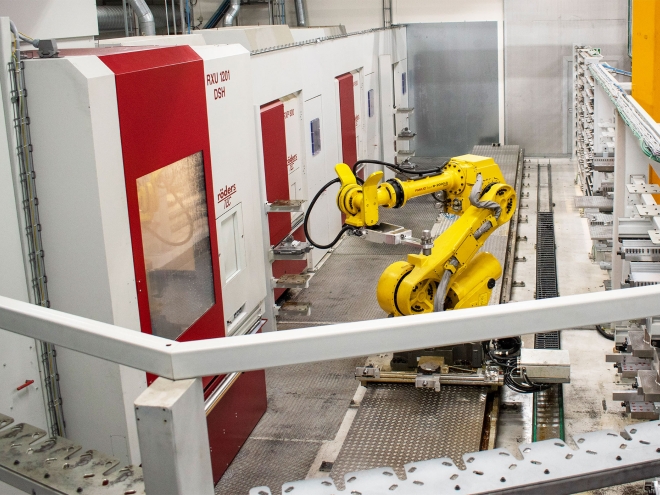

At Idé-Pro, we specialise in the design and manufacture of moulding tools for injection moulding, high-pressure die-casting (HPDC) and moulding of EPS/EPP parts. Our in-house toolf actory is powered by fully automated milling machines as well as our skilled toolmakers.

We have a large capacity, manufacturing up to 20 tools per week. With 3-axis, 4-axis, 5-axis and 6-axis CNC milling, we can machine tools with dimensions up to 2100 x 4000 x 1200 mm and up to 20 T.

After machining, the tools are assembled and prepared by a toolmaker before being ready for injection moulding, high-pressure die-casting or EPS/EPP moulding.

Our expertise within tool manufacturing spans over aluminium and steel tools and we manufacture with varying hardnesses, for injection moulding, high pressure die casting and EPS/EPP moulding.

The choice between aluminium or steel tools depends on the material and desired production scale, but our aluminium tools can be used for prototyping, start-up and small series production.

Our focus is on delivering high-performance and durable tools that accelerate the production process while keeping costs to a minimum.

Injection moulding in aluminium tools: Efficiency and Cost Savings

For injection moulding and EPS/EPP moulding, the tool is made from aluminium so it can be manufactured quickly and efficiently at the lowest possible cost. Suitable for prototyping as well as start-up and small series production, our aluminium tools are ideal for testing and fine-tuning your designs.

HPDC in steel tools: Durability and Precision

To high pressure die cast aluminium, magnesium and zinc parts, the tool requires higher hardness, which is why it is made from steel.

Our expertise - Your advantage

With years of experience in the industry, we combine technical know-how with innovative design to develop tools that help you stay competitive in the market with your prototypes. Our dedication to quality and precision makes us your preferred partner in manufacturing tools for prototyping and serial production.

Our tool factory, injection moulding, high pressure die casting and EPS/EPP moulding are all under one roof. This means that transport time between the departments is measured in minutes, not days or weeks, ensuring faster delivery and a more efficient production process.

We are also very flexible with tool changes and adjustments, which our skilled toolmakers take care of.

Contact us today to discuss how Idea-Pro can provide customised moulding tool solutions that meet your specific injection moulding, high pressure die casting and EPS/EPP requirements. We look forward to helping you achieve excellent results and increase the efficiency of your production.